CLEAR AIR.

CLEAR FUTURE.

Your apprenticeship at Scheuch – find your passion.

A job in the technology sector. A job for the environment. A job with a future. You can’t decide? You don’t have to. You’ll learn all of this and more from us. As the leading family business in air technology, climate protection and further training are not just buzzwords for us, they are matters that are close to our hearts. We will foster your talents regardless of the apprenticeship you choose at Scheuch. We’ll support you in finding, developing and achieving your passion. We do this through teamwork, exciting work and a highly professional apprenticeship at eye level.

Our apprenticeships

Welding. Grinding. Bolting. As a mechanical engineer, you combine mechanics and technology with machines that drive the world. You’ll learn how to use diagrams and drawings to produce and assembly parts, as well as to commission systems and devices.

After your apprenticeship, you’ll be a pro in

- Using tools, work aids and materials

Equipment, devices, (CNC) machines and systems - Programming CNC machines

- Welding technology

- Electrical engineering, pneumatics, hydraulics

- Electronics, mechanics

- Manufacturing machine components and systems

Facts:

- Apprenticeship duration: 3.5 years

- Vocational school: Attnang-Puchheim

- Remuneration according to the collective bargaining agreement for the metalworking industry

Separating. Shaping. Cutting. As a metalworker and sheet metal engineer, you shape the heart of metal. You use the most modern techniques to cut metals and sheet metals in order to give them their final shape.

After your apprenticeship, you’ll be a pro in

- Using tools, work aids and materials for metalworking

- Equipment and device construction

- Operating CNC machines and systems

- Computer-aided drawing and ¬design (CAD)

- Separation and joining techniques in metalworking and sheet metal engineering

- Components and drives for electrical engineering and electronics, hydraulics and pneumatics

- Surface treatment, surface protection and corrosion protection

- Structural analysis and building physics

- Principles of structural design, structural attachment and assembly techniques

Facts:

- Apprenticeship duration: 3.5 years

- Vocational school: Attnang-Puchheim

- Remuneration according to the collective bargaining agreement for the metalworking industry

Constructing. Machining. Creating. As a structural steel engineer, you create impressive structures. You will learn various techniques for machining materials and use drawings to manufacture structures.

After your apprenticeship, you’ll be a pro in

- Using electrical, pneumatic and hydraulic tools

- Using work aids and materials

- CNC machines

- Welding and cutting techniques

- Maintenance work

- Manufacturing, assembling and fitting structures for systems

- Structural analysis and strength apprenticeship

- Surface treatment and surface protection

Facts:

- Apprenticeship duration: 3.5 years

- Vocational school: Attnang-Puchheim

- Remuneration according to the collective bargaining agreement for the metalworking industry

Turning. Milling. Drilling. As a machinist, you send swarf flying and create unique masterpieces precisely from raw materials.

After your apprenticeship, you’ll be a pro in

- Creating and programming production programs for CNC machines

- Adopting and adjusting (CAD) designs in production programs

- Defining the machining parameters and finding the appropriate machining tools

- Setting up and operating tool machines and production systems

- Finding, isolating and remedying errors, faults and interruptions

Facts:

- Apprenticeship duration: 3.5 years

- Vocational school: Attnang-Puchheim

- Remuneration according to the collective bargaining agreement for the metalworking industry

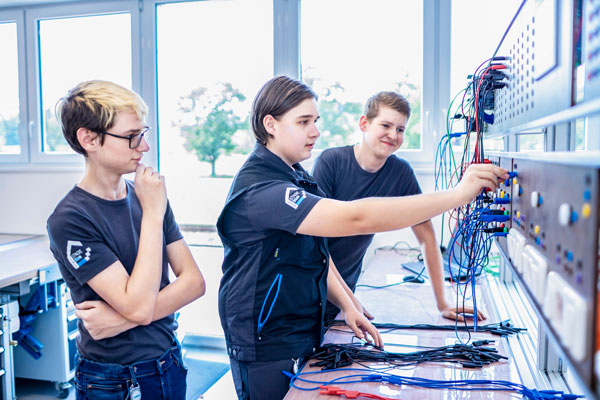

Planning. Fitting. Installing. As an electrician with a main module in system and operating technology, you juggle currents and switches to bring technology to life. You will learn everything about electrical devices, systems and plants.

After your apprenticeship, you’ll be a pro in

- Installing electrical systems and devices

- Repairs and maintenance work

- Finding and remedying faults

- Controlling systems and devices

Facts:

- Apprenticeship duration: 3.5 years

- Vocational school: Gmunden

- Remuneration according to the collective bargaining agreement for the metalworking industry

Building. Maintaining. Digitising. As a mechatronics engineer, you’re always tinkering. In the main automation technology module, you’ll commission automation systems, control systems and regulation systems for computer-controlled machines. You’re well versed in technology. That’s because you assemble mechanical, electrical, pneumatic/hydraulic and information technology parts, repair and maintain them. Furthermore, you can bring your own ideas into digitisation and therefore constantly develop our products further.

After your apprenticeship, you’ll be a pro in

- Setting up, commissioning and testing measuring equipment for hydraulics and pneumatics

- Setting up, optimising and maintaining automation systems and mechatronic systems

- Controlling and programming industrial robots (using the PLC)

- Compiling, reading and applying technical documentation

- Company-specific mechatronic technical and product areas

- Systematically finding, isolating and remedying errors and faults

Facts:

- Apprenticeship duration: 3.5 years (foundation module + main module)

- Vocational school: Linz

- Remuneration according to the collective bargaining agreement for the metalworking industry

Planning. Implementing. Monitoring. As a process engineer, you ensure that everything runs smoothly. You’ll plan the use of the tools and equipment on production machines and systems, learn how to read work instructions and schedules. Furthermore, you’ll monitor and set up the production systems.

After your apprenticeship, you’ll be a pro in

- Operating production systems

- Controlling, planning and optimising processes

- Automation and process control engineering

- Compiling, reading and applying technical documents

- Inspections and implementing quality assurance measures

- Assisting with production and manufacturing planning

- Maintaining and repairing tools, machines and systems

Facts

- Apprenticeship duration: 3.5 years

- Vocational school: Attnang-Puchheim

- Remuneration according to the collective bargaining agreement for the metalworking industry

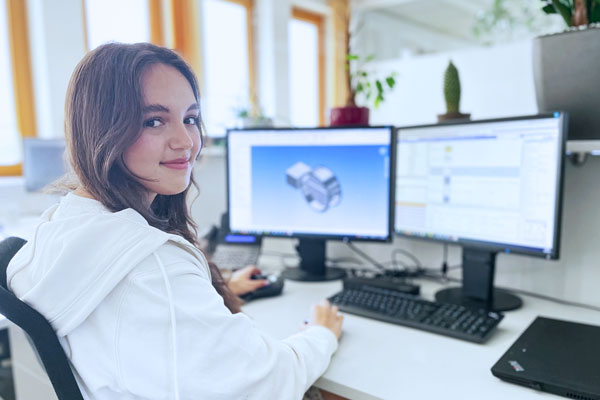

Planning. Thinking. Constructing. As a designer with a focus on mechanical engineering, you make ideas a reality and use virtual tools to create new things. You use a PC to create construction plans for various parts, devices, components and systems, and to the build the future one piece at a time on your screen.

After your apprenticeship, you’ll be a pro in

- Working according to sketches, designs and models

- Reading and applying technical documents (e. g. diagrams, etc.)

- Planning work flows

- Performing technical calculations, e. g. lengths, times, angles, speeds, etc.

- Developing processes for production and assembly

- Creating technical drawings, diagrams and documents using 2D or 3D programs

Facts:

- Apprenticeship duration: 4 years

- Vocational school: Linz

- Remuneration according to the collective bargaining agreement for the metalworking industry

Budgeting. Checking. Accounting. As a finance and accounting assistant, you are the treasurer of our company. You will monitor all incoming and outgoing payments, and are responsible for ongoing records of business transactions. Your support is required for annual reports, as well as payroll and salary accounting.

After your apprenticeship, you’ll be a pro in

- Completing bookkeeping tasks

- Recording and evaluating data and operating figures

- Preparing financial accounting activities

- Performing payroll and salary accounting

- Performing settlement with social insurance bodies and tax authorities

- Calculating running contributions

- Creating inventories and preliminary VAT returns

Facts

- Apprenticeship duration: 3 years

- Vocational school: Linz

- Remuneration according to the collective bargaining agreement for the metalworking industry

Organising. Coordinating. Managing. As an operational logistics specialist, you pull the strings. You’ll organise logistics and take on organisational tasks in the stockroom, purchasing and customs clearance.

After your apprenticeship, you’ll be a pro in

- Managing and monitoring stock

- Organising transport

- Inspecting and accepting goods

- Placing material into stock, relocating it and removing it from stock

- Operating and maintaining technical equipment and facilities

- Knowledge of the purchasing area

- Evaluating, creating and maintaining statistics, files and indexes

- Performing administrative work

- Expertise in customs clearance

Facts:

- Apprenticeship duration: 3 years

- Vocational school: Ried

- Remuneration according to the collective bargaining agreement for the metalworking industry

Painting. Spraying. Dipping. As a coating specialist, you are the creative artist that turns the surfaces into eye-catchers. You will produce coating layers on different components and learn how to use different techniques to prepare the surfaces for the protective coats.

After your apprenticeship, you’ll be a pro in

- Sound knowledge of paints and coating materials

- Proper application of coatings and coating materials to different subsurfaces using a multitude of application devices

- Repairing surfaces using targeted corrosion protection, proper priming, smoothing, filling and sanding using various techniques

- Digital tools and devices such as airless systems, airmix devices and gravity spray guns

- Identifying and remedying possible faults in coatings

- Performing thorough quality controls on workpieces

- Creating technical documentation

Facts:

- Apprenticeship duration: 3 years

- Vocational school: BS Wels 1

- Remuneration according to the collective bargaining agreement for the metalworking industry

Designing. Planning. Repairing. As an information technology system technician, you’re on the ball. That’s because you provide employees with IT devices and the appropriate software. At the same time, you design and plan networks, servers, data storage and backup systems. If something breaks, you’re the pro that repairs it. You also perform maintenance, expansions and tests, and create user manuals.

After your apprenticeship, you’ll be a pro in

- Analysing IT-related requirements and creating concepts

- Installing devices and networks, as well as connecting, configuring, testing and maintaining them

- Finding, isolating and remedying errors and faults

- Setting up and looking after single workstations and network stations

- Advising and training users

- Creating documentation, backing up data

Facts:

- Apprenticeship duration: 4 years

- Vocational school: Linz BS 2

- Remuneration according to the collective bargaining agreement for the metalworking industry

Coding. Setting up. Documenting. As an Information technology application developer – coding you will become a programming genius. You will create software applications for computer and IT systems, industry-specific software and browser applications, program applications, set up databases, create user accesses, perform tests and document the processes.

After your apprenticeship, you’ll be a pro in

- Creating project, time and resource plans, defining process steps

- Programming applications or partial applications

- Determining and analysing data, selecting and implementing data models or data management systems

- Developing database accesses and implementing data security measures

- Setting up user interfaces

- Developing test cases, performing and documenting tests, and rectifying errors

- Creating technical documentation and user manuals, providing training

- Installing and updating software, performing service work

Facts:

- Apprenticeship duration: 4 years

- Vocational school: Linz

- Remuneration according to the collective bargaining agreement for the metalworking industry

Our apprenticeships

Your contact person